Workshop 10: Packaged food. Food waste reduction solutions in food packaging for take-away

On 6th July we carried out the tenth online thematic workshop of Global Foodture: “Packaged food. Food waste reduction solutions in food packaging for take-away” with more than 240 registered participants from 30 different countries.

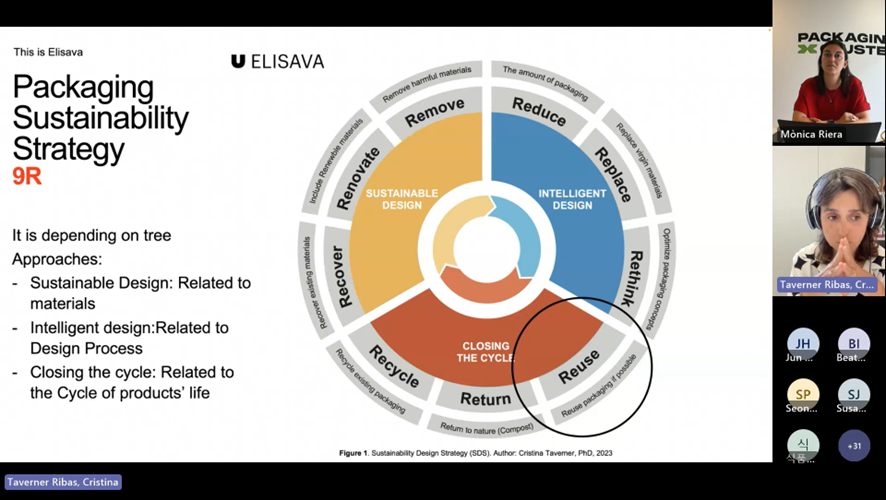

Reduce, reuse and recycle. The European Union generates around 88 million tonnes of food waste every year. This means that 20% of the total food production is lost or wasted. The main origin of food waste are households. However, there is still a 26% from food service and 13% from retail that can be reduced with the efforts of all the industry players. We saw 3R applied solutions for retail and take away.

Thank you Cristina Taverner (ELISAVA), Jun Hur (Foodpolis), David Esteban (Retoornado), Oriol Segarra (Bumerang), Fernando Rodríguez-Mata (New ERA), Anand Subramanian (ecoSPIRITS), Cristina Alonso (AREAS), and Inmaculada Lorente (ITENE) for your inputs on sustainable packaging.

The workshop was moderated by Mònica Riera (Packaging Cluster).

The opening was provided by Cristina Taverner, Head of Academia and Business Relations Department and Graduate & Undergraduate Lecturer at ELISAVA, and Jun Hur from Foodpolis, our local partner in South Korea. They both introduced the trends and innovations in sustainable packaging in Europe and Asia, with focus on the food sector.

The first masterclass was about “Circular take-away solutions”.

The first masterclass was opened by David Esteban, CEO of EcoPack Ideas. David introduced Retoornado, the first reusable packaging ecosystem that proposes closing the loop on reusability. From packaging eco-hygienic design to logistics, washing step and digital engagement in open, hybrid and closed circuits.

Then, Oriol Segarra, CEO of Bûmerang talked about reusable packaging systems: creating convenience, sustainability, and scalability for take-away packaging. In the last years, plastic has been under attack, we do not have a material problem but a consumption problem. We need to move away from single use to multiple use packaging and the way to do it is through reusable packaging sysems.

Finally, Fernando Rodríguez-Mata, General Director of New ERA (European Reuse Alliance) discussed on how EU policy can promote the reusable packaging industry, focusing on the take-away sector. New ERA is the trade association representing organisations that promote and offer reusable packaging solutions across Europe (being EcoPack Ideas and Bûmerang two of them). One of their main priorities is to help policymakers in establishing the conditions for accelerating the transition towards reuse systems in a robust, cost-effective, and environmentally sound way.

The second masterclass was about “Sustainable retail and HORECA”.

This second masterclass was kicked off by Anand Subramanian from ecoSPIRITS. He showed the audience how are they revolutionizing wine and spirits distribution, embracing circular packaging for a sustainable future. Anand introduced ecoSPIRITS and what are their mission and circular packaging technology, exposing some examples of wine and spirits industry use cases.

Then, Cristina Alonso, from AREAS, explained what the company is doing to implement a reuse system in the foodservice sector. AREAS is at the forefront of implementing reusable packaging in their restaurants, making them one of the pioneers in the foodservice industry. In such a volatile and unpredictable scenery and a strict regulations already in action, AREAS puts the accent in its commitment with the best environmental practices. How are they decreasing the

use of single-use plastics in their shops? Which is the coming future in the HORECA Market? We need to make changes in our businesses. Reusable smallware is an opportunity in the short and long term.

The masterclass was closed by Inmaculada Lorente from ITENE, who introduced the SHEALTHY project and the ethylene colorimetric ink for monitoring fruit ripening they are developing. The SHEALTHY project focuses on improving the safety, nutritional quality, and shelf life of minimally processed fruits and vegetables through non-thermal sanitization, preservation, and stabilization methods. As part of this project, ITENE has developed an ink that can detect the concentration of external ethylene gas. The ink changes its colour based on the time and concentration of ethylene exposure, with a lower sensitivity limit of 20 parts per million (ppm). Initially light brown, the ink turns dark blue in the presence of ethylene. Various factors such as compound concentration, binders, printing substrates, ethylene concentrations, and humidity conditions have been evaluated for the ink’s performance. This innovative ink has shown promising potential for enhancing fruit management and control before commercialization, reducing losses, and improving fruit quality throughout the supply chain.

The online workshop was finalised with a Q&A moderated by Mònica Riera (Packaging Cluster).

Are you interested in international innovation collaboration with Asian partners in the field of sustainable packaging? Please visit the website for more information, and register for the online thematic workshops or online matchmaking.

Discover all the details in the full webinar below.